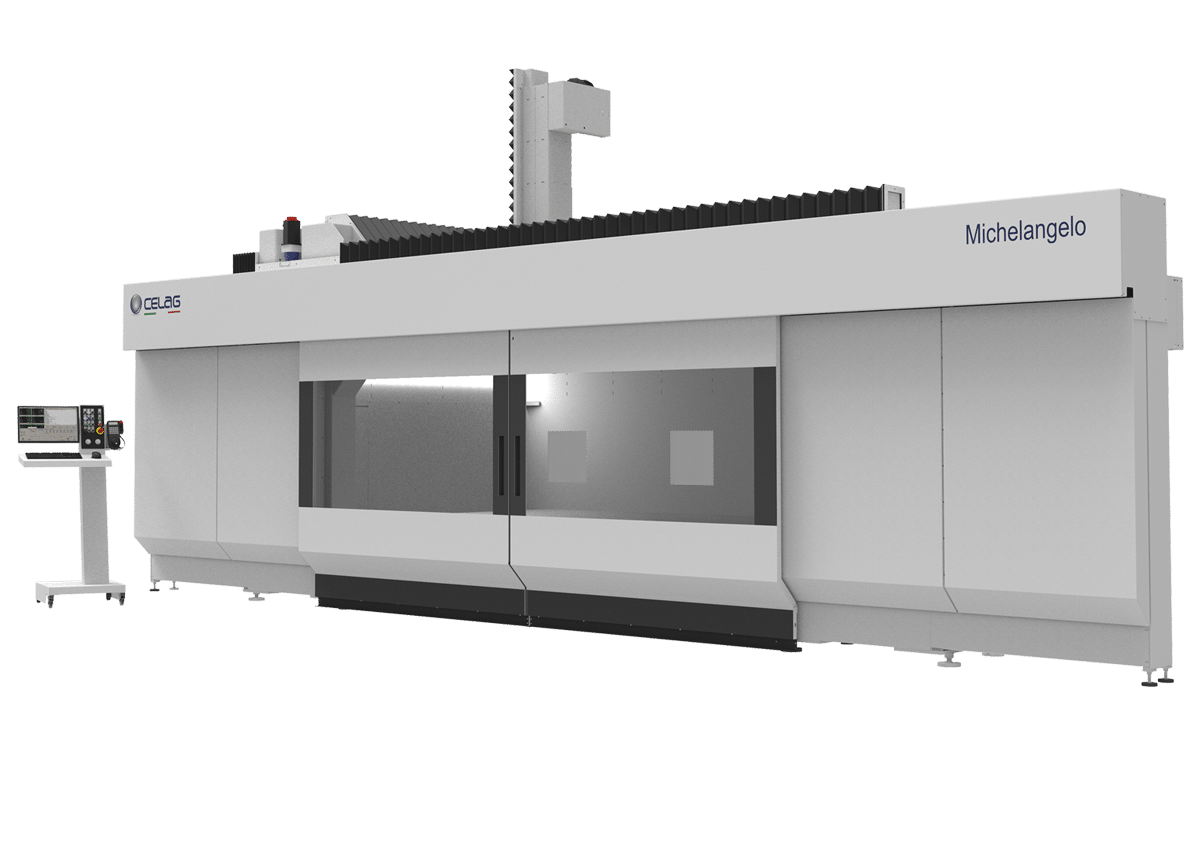

The best quality, flexibility and productivity

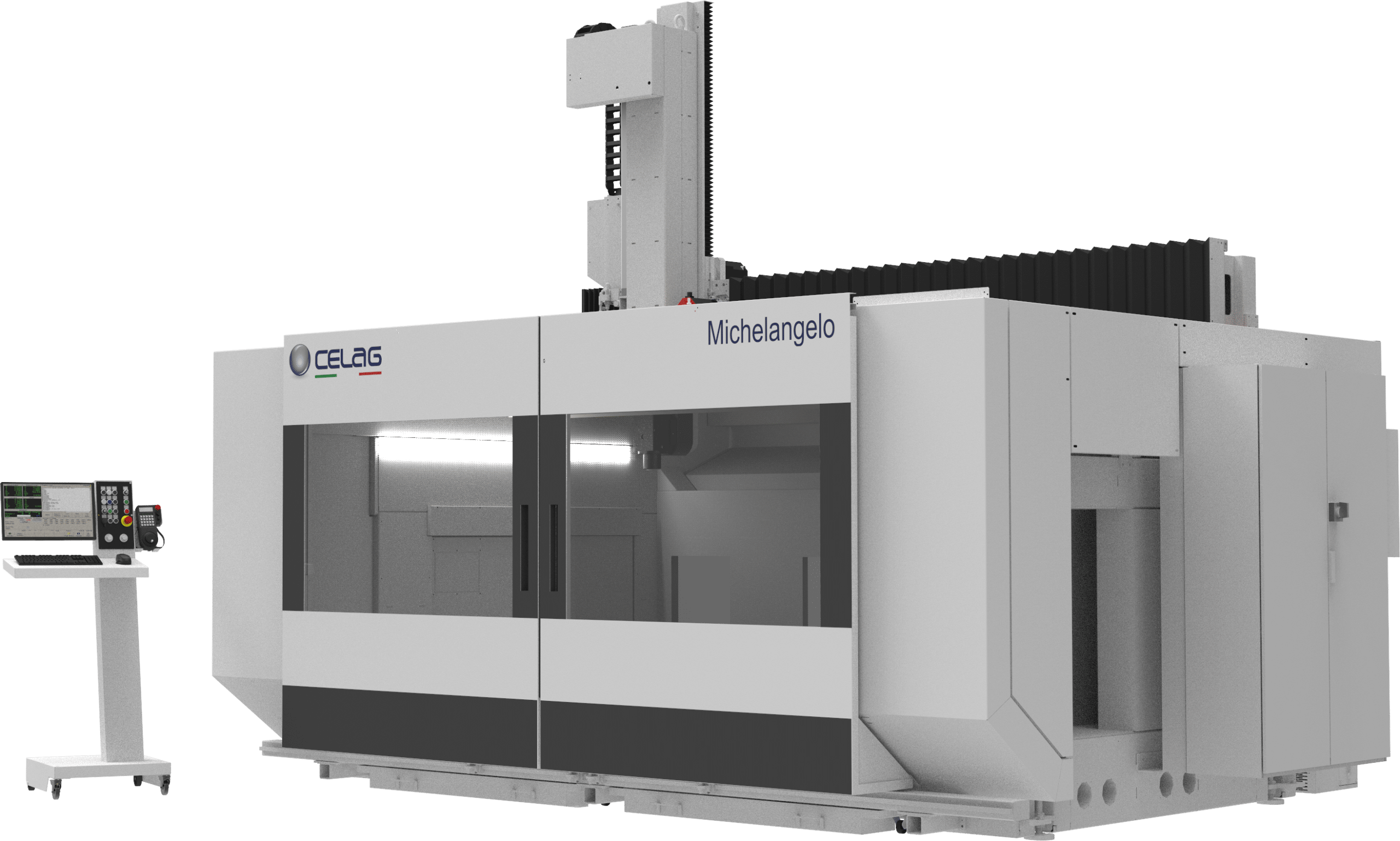

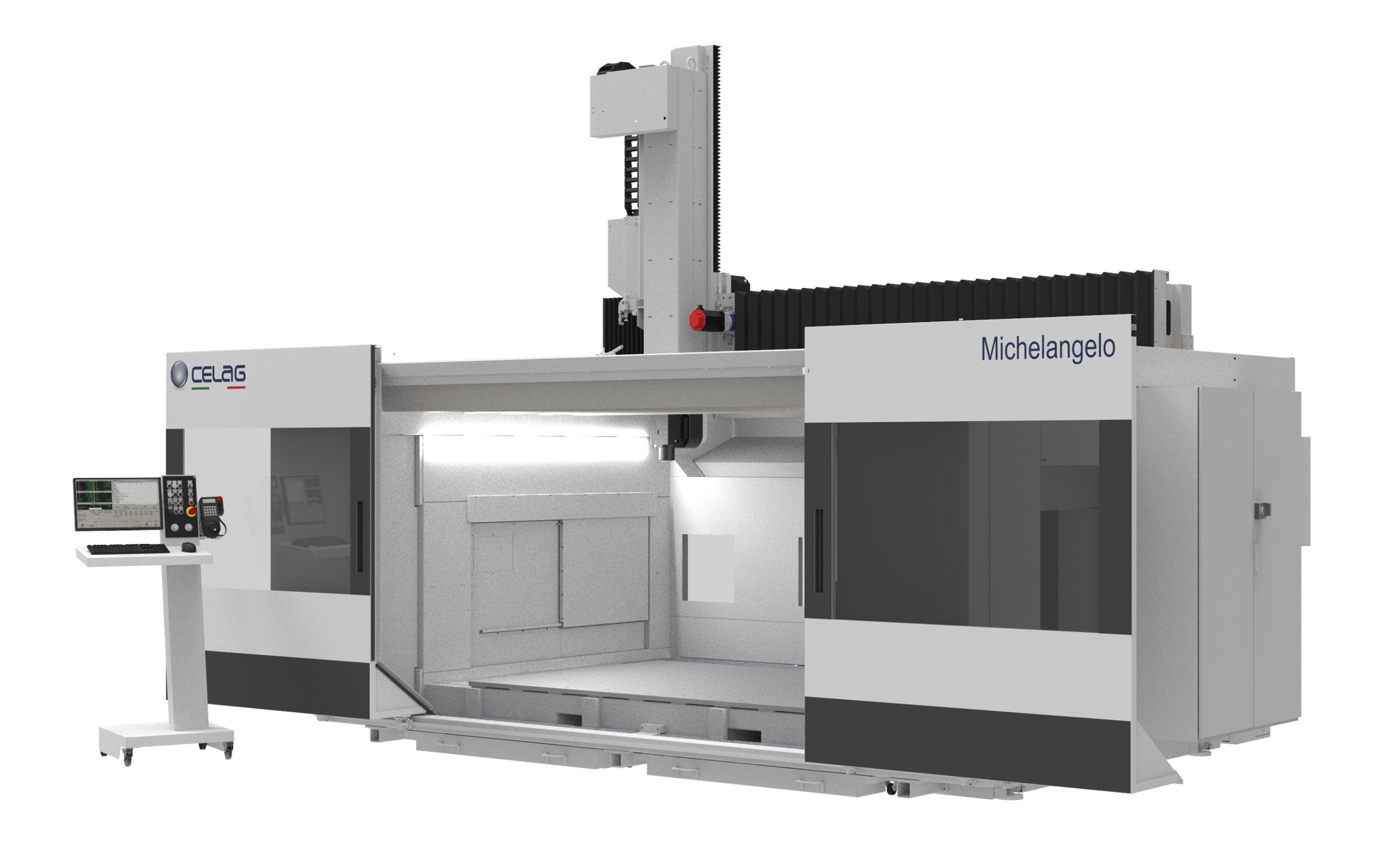

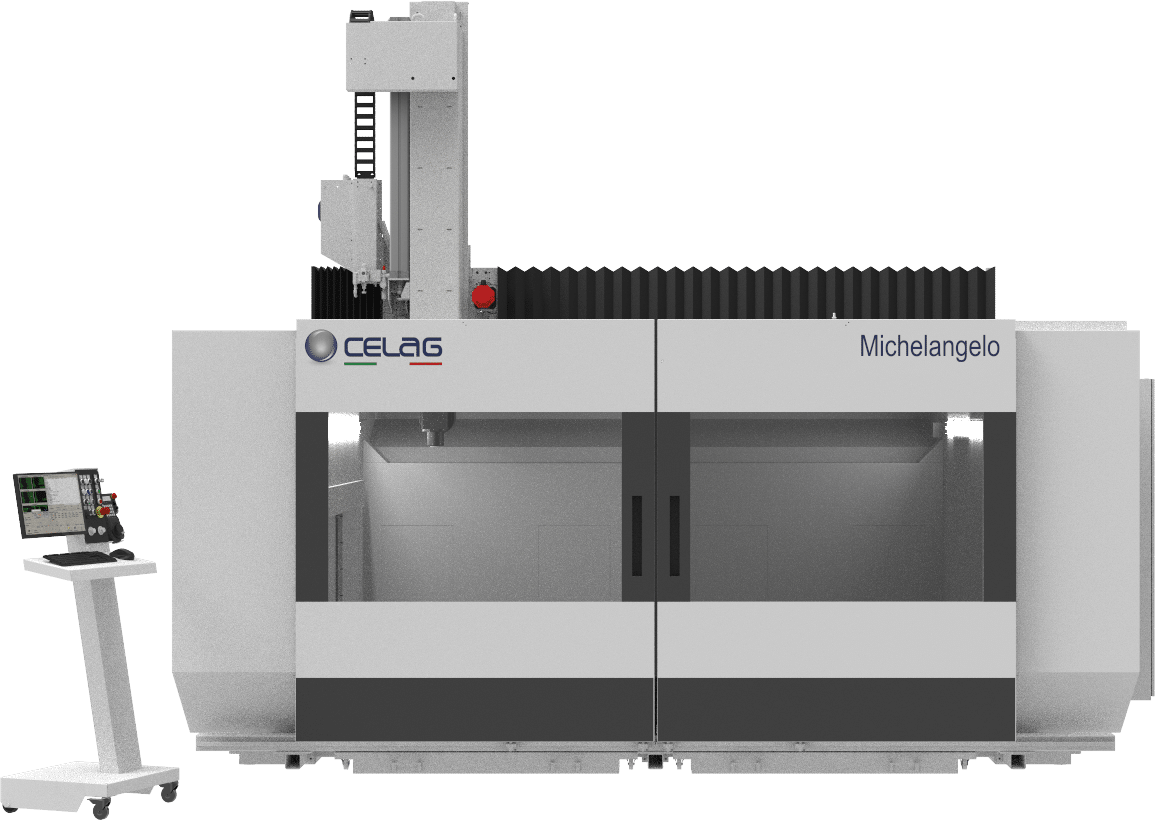

Michelangelo is a range of latest generation 5-axis interpolating machining centres, designed to work the most advanced material; composites, special resins, plastics, aluminium, light alloys, wood.

A compact design with a large machining volume together with high precision and reliability make it the ideal choice to be efficient in the company and offer the highest quality available today.

the top of 5-axis technology

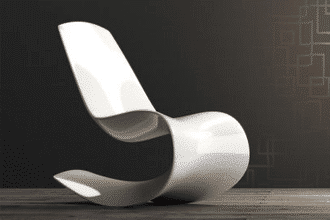

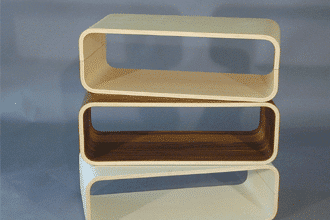

Created to perform at high speed on the most complex 3D shapes, it is used in many sectors, from molds to thermoformed components to industrial components for the automotive industry, boats, aeronautics, furniture and more.

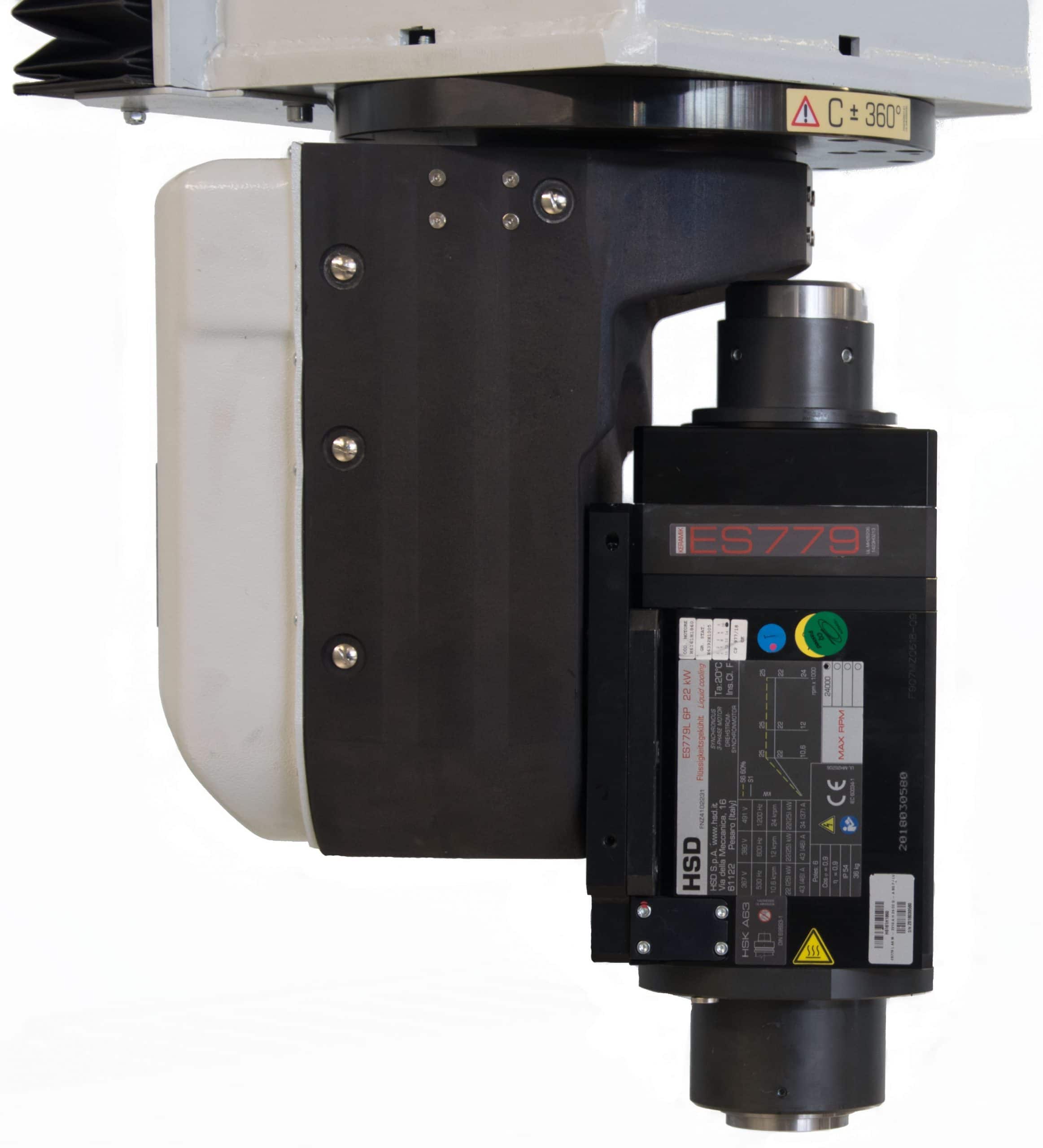

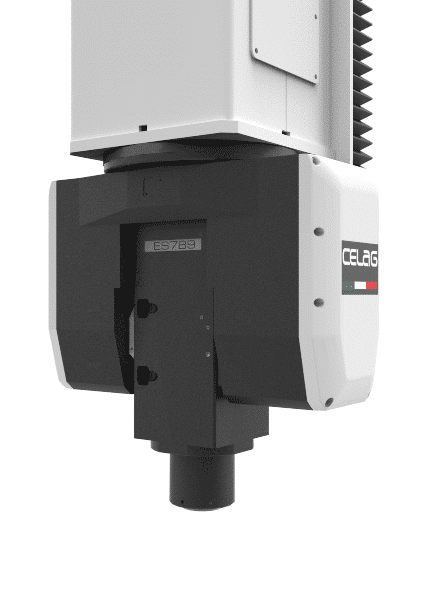

OPERATING UNITS

High torque even at low speed. The HSK interface guarantees torque transmission, speed and precision when changing tools.

| Electro-spindles range | Use |

|---|---|

| Power 10/12 kW Asyn Type HSK F63 Max speed 24.000 rpm Nominal speed 7.500 rpm Liquid cooled |

Suitable for plastics, composites, wood machining |

| Power 15/18 kW Asyn Type HSK F63 / HSK A63 Max speed 24.000 rpm Nominal speed 12.000 rpm Liquid cooled |

Suitable for composites, aluminium machining |

| Power 22/25 kW Synch Type HSK F63 / HSK A63 Max speed 24.000 rpm Nominal speed 10.600 rpm Liquid cooled |

Suitable for composites, aluminium machining |

SUCTION AND CLOSING

The Michelangelo HL machining center can be equipped with an extremely effective suction system to be able to deal with even the most difficult materials.

The Michelangelo HL work center can be equipped with a system of sky bellows that limit the escape of fumes, dust and shavings from the work area. In addition to preserving the machine mechanics, this application also helps to maintain a cleaner and healthier environment for the operator

MATERIALS TREATED

The machining centers, as we said earlier, are widespread and appreciated in industrial processes also for their ability to work many materials.

- Plastic

- Resins

- Composite materials

- Aluminum

- Advanced materials

- Polyurethane

- Wood

- MDF

INDUSTRIAL APPLICATIONS

The 5-axis mechanical processes are used to make components and semi-finished products in different sectors, among which the most relevant are:

AUTOMOTIVE INDUSTRY: cnc in the automotive industry are used to make resin and aluminum molds, style models, trimming of plastic, carbon and composite components

MEDICAL INDUSTRY: cnc in the medical industry are used to cope with an increasingly high demand for processing dictated by the aging population that is playing an important role in the growth of the sector.

NAUTICAL INDUSTRY: cnc in the nautical industry are used to meet the most diverse needs that extend from shipbuilding to pleasure boats with the need to work on different types of materials; The machine tools will be used for processes that start from the modeling and trimming of hulls up to the smallest details in fiberglass and composite.

AEROSPACE INDUSTRY: the aerospace sector imposes severe requirements both in terms of material and complex shapes. CNCs in the aerospace industry are used for the machining of structural parts such as wings, bulkheads, trolley systems, engine parts and interior components using a wide range of high-tech complex materials and alloys ranging from titanium to carbon to aluminu.

DATA SHEET

| Michelangelo HF | ||

| Electro-spindles | Power 10/12 kW Power 15/18 kW Power 22/25 kW See table pag 7 |

|

| Axis | Axis X,Y,Z: pignon – rack B/C: hollow shaft |

|

| Table | Steel T-slot table Aluminum flat table Aluminum matrix table Phenol resin matrix table Other on request |

|

| Axis range/ Working area (spindle nose) |

X = 2.840mm Y = 1.740mm Z = 1.250mm B = ± 120 ° C = ± 360 ° |

X = 3.000mm Y = 1.900mm Z = 1.200mm B = ± 120 ° C = ± 360 ° |

| Rapid Traverse | X-Y-Z = 80 m/min B/C = 75 °/sec |

X-Y-Z = 80 m/min B/C = 200 °/sec |

| Tool warehouse | 8-position travelling linear tool warehouse 16-position travelling linear tool warehouse 24-position travelling linear tool warehouse Other on request |

|

ASK FOR INFORMATION

You might also be interested:

Thanks to its characteristics, the MICHELANGELO HL machining center proves to be the ideal choice for trimming composite materials, for high-speed milling of wood, resins, light alloys and aluminum.

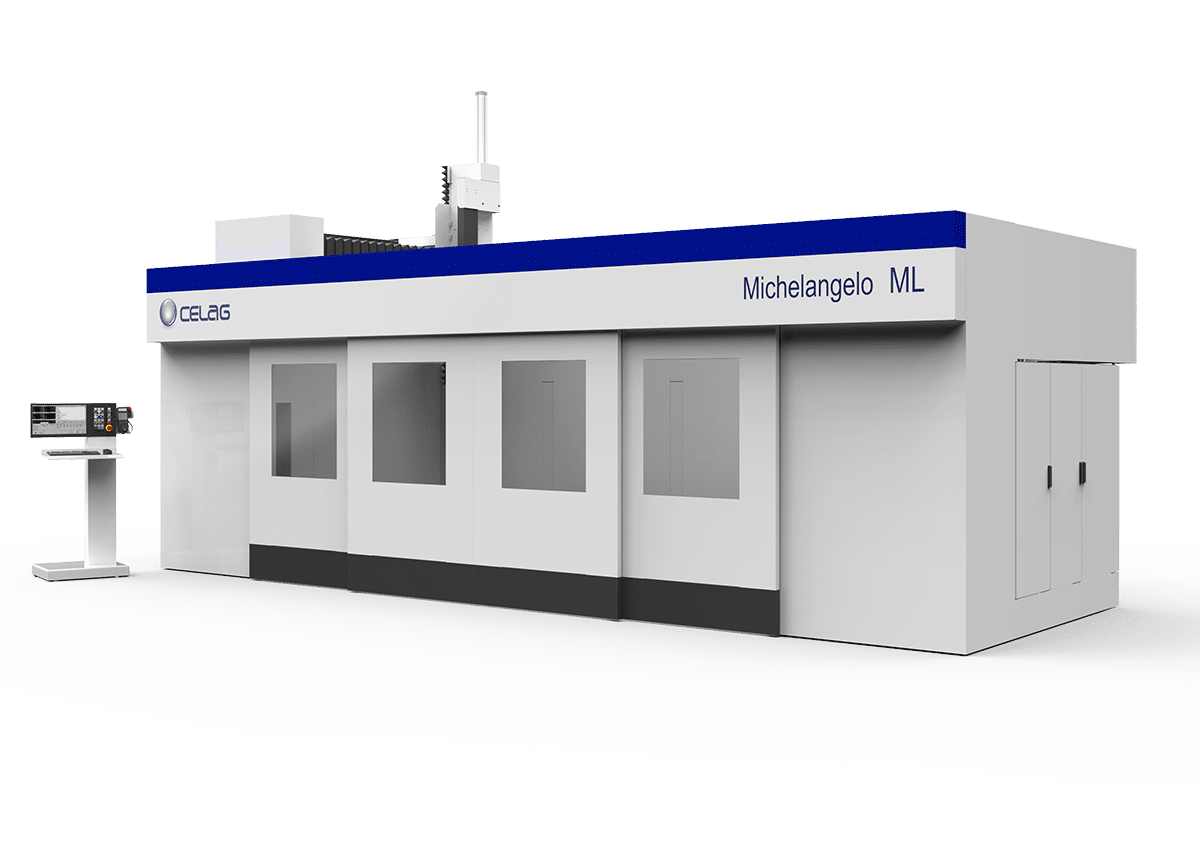

The Michelangelo ML 5-axis machining center is the ideal solution for trimming plastic and composite materials, which thanks to its technical characteristics ensure high productivity and production quality.